Tom Osman

Injection Moulding Trials

Our knowledge of part designs and moulding simulation means that we can assist your suppliers in setting their injection moulding machines.

Impression Technologies

Demonstrating the industrial capabilities of HFQ® Technology.

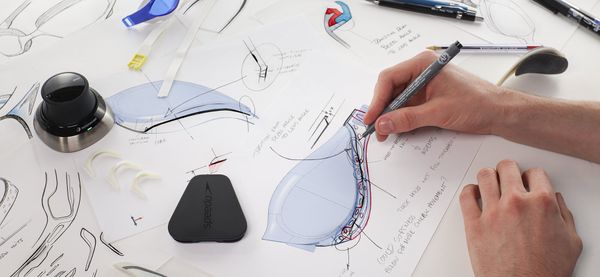

Plastic Part Design and Manufacture

Raymont Osman Product Design have a vast portfolio of product design and manufacture using a range of plastics, giving us the edge when it comes to determining the material make-up of your product.

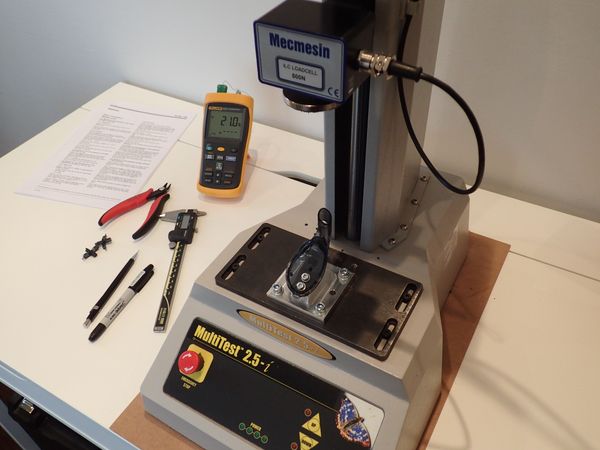

Qualification

We can check the products are made and assembled correctly and test that they are still being made correctly if production problems occur

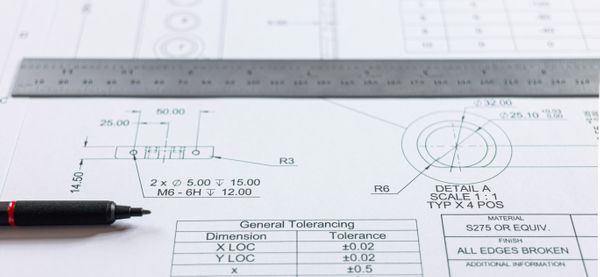

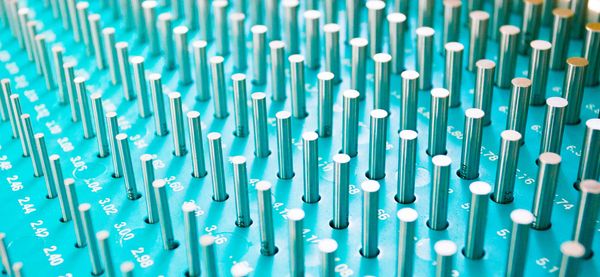

Tolerance Analysis

Specifying the size of the parts and analysing the stack up of tolerances so components and assemblies work regardless of any production variation.

Solid Model Design

Solid Model Design is the most traditional method of design, used primarily for machined components. We have extensive experience in designing CNC'd parts, having spent many years working with manufacturers across a variety of sectors.

Technical Drawings

Creating technical drawings from 3D CAD and calculating tolerances allows you to control the quality and costs from your suppliers and tells your customers exactly what they are buying.

Reverse Engineering, Teardown Reports and Analysis

At Raymont-Osman, we offer a comprehensive range of reverse engineering, teardown and analysis services to help you get a better understanding of your competitors' products, identify potential design improvements, and enhance your own product development process.

Surfacing

Raymont-Osman designers possess extensive training and experience in advanced surface modelling, enabling them to create A-class products that look as good as they perform

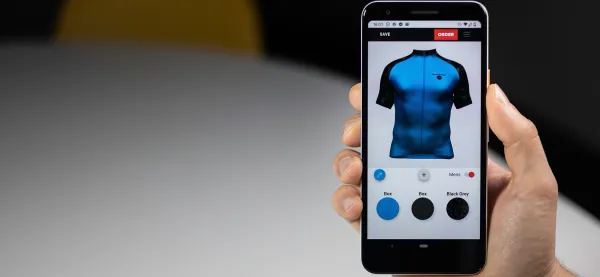

Photorealistic Rendering, CGI & Animations

At Raymont-Osman, we recognize that the visual appeal of a product is as important as its functionality. Our photorealistic rendering, CGI, and animation services create stunning visuals that accurately represent your product, its features and benefits and help you market it to potential customers.

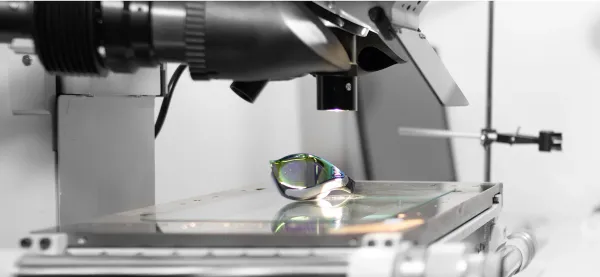

Simulation - Optical, FEA, CFD and Motion Analysis

At Raymont-Osman, we offer a range of virtual simulations and analysis, including Optical, FEA, Injection Moulding, CFD, and Motion Analysis. These tools allow us to save time and costs by identifying and addressing potential design issues early in the process.

Prototypes

We take pride in our ability to bring your vision to life through the creation of physical prototypes. Our state-of-the-art workshop boasts cutting-edge facilities for handcrafting and 3D printing, enabling us to produce prototypes that are unparalleled in their accuracy and detail.

Design of Assembly and Test Equipment

For some products, the method of making the it, is as critical as the final product.

Material Selection

Through thorough analysis and testing we ensure that the perfect material is used for our client's products. The choice of materials can make or literally break a product!

Simulation in Design

Our wide range of simulation methods will help you when you require validation of your initial idea ahead of development

Looking to get started?

We love hearing from creative ambitious businesses and individuals who are looking to make their dream a reality. Take advantage of our free discovery call. A complimentary 30 minute consultation call with one of our expert design consultants. Book Now